Silicone Putty

Description:

Silicone putty is great to make molds either with simple or intricate patterns.It have FDA Certificate and excellent for high-detail molds and complex design. Also it very suitable for making molds for resins, gypsum , concrete etc.

Appearance:

Part A: white color

B: blue color, or Green , or Red Etc.

Features:

1) Platinum-based (environmental,odorless and nontoxic)

2) Delicate design available

3) Mixing ration: 1:1 are available

4)Easy de-molding

5) Excellent resistance to weather, temperature, aging, acid & aging-Proofing. High resistance to high temperature and aging(resist 200 to 450°C)

Technology Date Sheet:

| Item | Silicone Putty | ||||

| Product (Catalyzed A+B) | SP40# | SP35# | SP30# | SP25# | SP20# |

| Hardness ( A) | 40±2 | 35±2 | 30±2 | 25±2 | 20±2 |

| Mix Ratio ( A:B by Weight) | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

| Color | A: White B:Colored | A: White B:Colored | A: White B:Colored | A: White B:Colored | A: White B:Colored |

| Pot life (mins) at 25°C | 2-3 | 2-3 | 2-3 | 2-3 | 2-3 |

| Cured time (Mins) at 25°C | 50-60 | 50-60 | 50-60 | 50-60 | 50-60 |

| Shrinkage (%) | 0.1 | 0.1 | 0.1 | 0.1 | 0.1 |

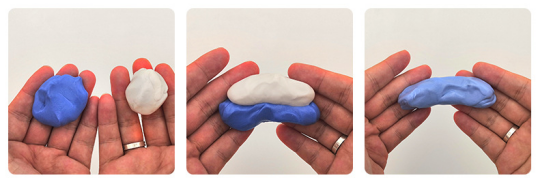

Operation Ways :

1. Take A and B exactly amount , and mixed then together evenly

2. Put the mixed silicone rubber on the pallet , and then put the pallet on the booth mold , after 3 mins later, then can demould .

Shelf Life:

1Year at least, stored in a cool and dry place under room temperature 25℃

Packing:

0.5kgs, 1kgs, or 20kgs per drum

Notices:

1. No contact with your Food or Drinking Water etc.

2. Keep Out Of Reach Of Children.

3 .As addition cure silicone is a kind of platinum cure system ,which will be easy to cause uncure problem ,so Kindly follow the tips below :

1)Do not mix with liquid condensation silicone rubber or even the tool which used for condensation silicone

2)Do not mix with organic matter which contains N, S, P organics and ionic compound like Sn, As,Hg, Ph,

3)Do not add any pigment or powder into the addition cure silicone rubber without any testing to prevent uncure problem